Advanced Sanitary Food Process Piping Solutions for Kansas City Food Processing Facilities

Advanced Sanitary Food Process Piping Solutions for Kansas City Food Processing Facilities

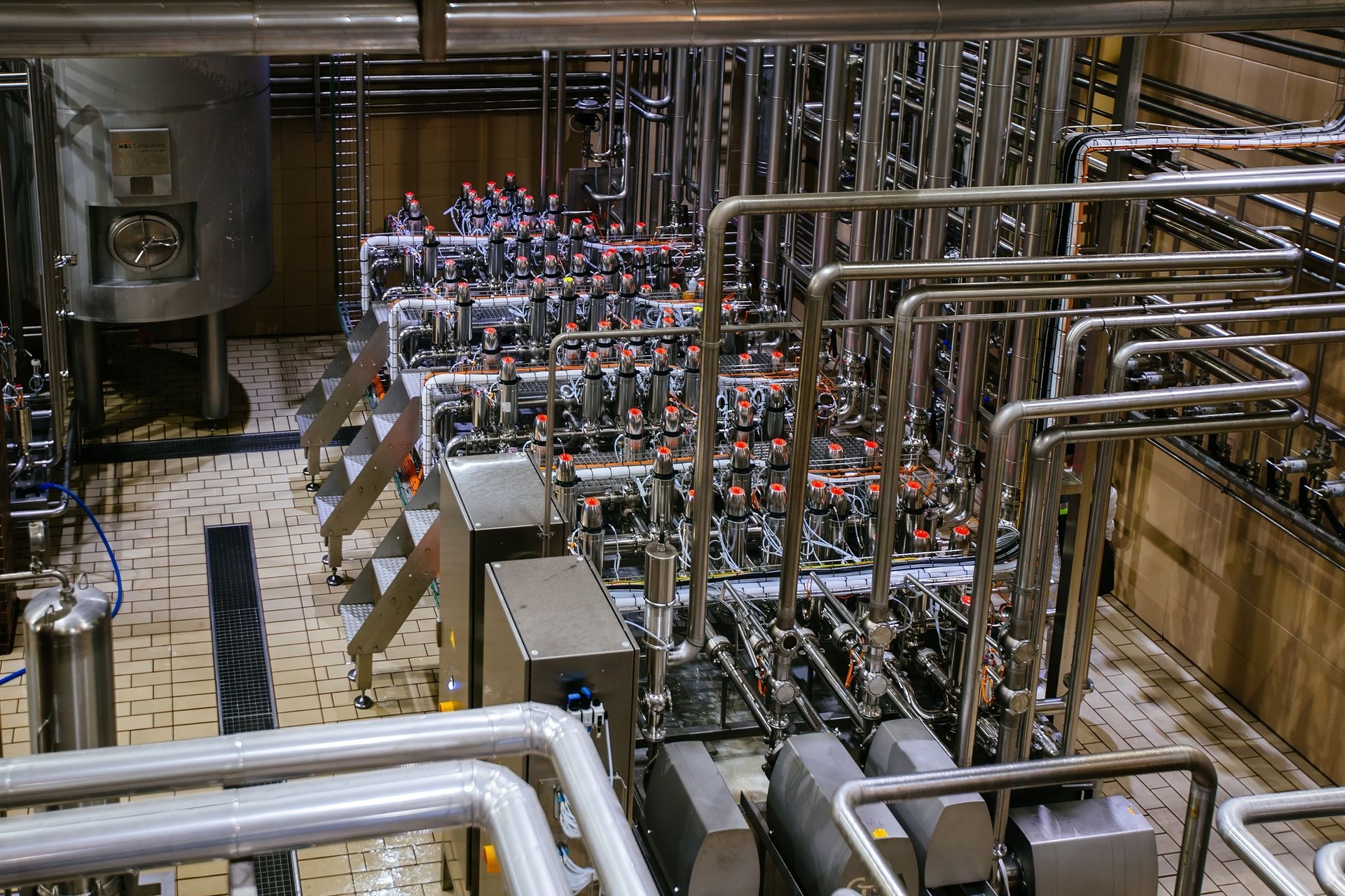

Food processing facilities require specialized piping systems that maintain the highest standards of hygiene and safety. Sanitary food process piping serves as the critical infrastructure that transports raw ingredients, intermediate products, and finished goods throughout your facility. The system must meet stringent regulatory requirements while supporting efficient operations.

Anderson Mechanical has served Kansas City area food processing operations for over 20 years, witnessing significant technological advances in sanitary piping design, installation, and maintenance. These innovations extend beyond regulatory compliance, delivering improved operational efficiency, enhanced safety protocols, and reduced maintenance requirements.

Understanding these technological developments helps facility managers make informed decisions about system upgrades and modernization projects.

Defining Sanitary Food Process Piping Requirements

Sanitary piping systems transport consumable products including liquids, semi-liquids, and certain solid materials in food and beverage manufacturing environments. These systems differ fundamentally from general industrial piping applications due to strict hygiene mandates.

Essential Design Characteristics

Sanitary food process piping must incorporate:

- Smooth interior surfaces preventing bacterial adhesion

- Seamless construction eliminating contamination harboring points

- Removable components enabling thorough cleaning access

- Corrosion-resistant materials ensuring long-term durability

- FDA-approved materials meeting food contact regulations

These requirements form the foundation for all sanitary piping system designs in regulated food processing environments.

Current Technological Innovations in Sanitary Piping

Enhanced Stainless Steel Alloy Development

Stainless steel remains the preferred material for sanitary applications, but recent metallurgical advances have improved performance characteristics significantly. Modern alloys demonstrate superior resistance to corrosion, pitting, and chemical degradation.

Advanced stainless steel grades including 316L with electropolished surfaces reduce biofilm formation, optimize flow characteristics, and maintain cleanliness standards over extended operational periods. These improvements particularly benefit facilities processing acidic products or operating at elevated temperatures.

Integrated Clean-in-Place System Design

Traditional sanitary piping required manual disassembly for cleaning procedures, creating significant downtime and labor requirements. Contemporary systems integrate seamlessly with automated Clean-in-Place (CIP) technology.

CIP systems enable automatic cleaning of internal piping surfaces without disassembly requirements. These systems circulate cleaning solutions, rinses, and sanitizing agents through piping networks at predetermined intervals, maintaining hygiene standards while minimizing operational disruption.

High-volume Kansas City operations benefit from reduced labor costs, improved cleaning consistency, and decreased contamination risks through automated CIP integration.

Zero Dead-Leg Valve Technology

Dead legs represent stagnant areas within piping systems where bacterial growth can occur. Modern sanitary piping incorporates zero dead-leg valves and fittings that eliminate flow stagnation points throughout the system.

This technology proves particularly critical for dairy processing, beverage manufacturing, and pharmaceutical applications where contamination risks must approach zero tolerance levels.

Modular Pre-Fabricated Assembly Systems

Pre-fabricated sanitary piping assemblies streamline installation processes while improving system reliability. Rather than field-welding individual components, entire sections undergo fabrication and testing in controlled environments before installation.

This approach reduces installation errors, ensures consistent quality standards, and minimizes facility downtime during system implementation or upgrades.

Advanced Monitoring and Detection Systems

Modern sensor technology enables real-time monitoring of flow rates, temperatures, and pressures throughout sanitary piping networks. These systems detect leaks, flow irregularities, or temperature deviations before they impact product quality or safety.

Contemporary facilities integrate monitoring systems with centralized control platforms, allowing operators to identify and address issues immediately, preventing costly production disruptions or contamination events.

Benefits for Kansas City Food Processing Operations

Kansas City food processing facilities operate under strict local health codes and regular inspection requirements. Outdated piping systems create compliance risks, contamination potential, and operational inefficiencies.

Operational Advantages

Modern sanitary piping systems deliver:

- Enhanced food safety profiles meeting regulatory standards

- Reduced cleaning time and associated labor costs

- Minimized contamination-related recall risks

- Increased equipment uptime and operational reliability

- Simplified regulatory compliance documentation

These benefits apply across diverse food processing applications including dairy processing, beverage bottling, snack manufacturing, and temperature-sensitive ingredient handling.

Anderson Mechanical's Specialized Piping Solutions

Anderson Mechanical develops customized sanitary piping solutions for each Kansas City facility's unique requirements. Production processes, facility layouts, and compliance obligations vary significantly across food processing operations.

Comprehensive Service Capabilities

Our specialized services include:

- Custom sanitary piping system design and engineering

- Professional installation using certified welders and food-grade components

- Clean-in-Place system integration and programming

- Preventive maintenance programs and compliance inspections

- Emergency repair services minimizing production disruption

Our experience with demanding food processing environments ensures systems meet both operational requirements and regulatory standards.

Identifying System Upgrade Requirements

Several indicators suggest sanitary piping systems require modernization:

Performance Warning Signs

- Recurring contamination issues or inspection failures

- Excessive cleaning labor requirements and associated costs

- Visible corrosion, pitting, or material degradation

- Outdated valve technology or connection methods

- Increasing maintenance frequency or leak repair needs

Facility managers noticing these issues should schedule professional system evaluations to identify cost-effective upgrade solutions that reduce operational risks while improving efficiency.

Implementing Modern Sanitary Piping Solutions

Whether facilities require complete system overhauls or targeted CIP system additions, Anderson Mechanical provides comprehensive solutions for Kansas City commercial and industrial clients. Our proven expertise in food-grade applications ensures precise implementation meeting all regulatory requirements.

Facility managers considering sanitary piping upgrades should evaluate current system performance, regulatory compliance status, and operational efficiency goals. Professional consultation helps identify optimal solutions balancing immediate needs with long-term operational objectives.

Contact Anderson Mechanical to discuss sanitary piping innovations applicable to your specific operation. Our team serves Kansas City, Lee Summit, Johnson County, and Jackson County with specialized food process piping expertise developed over two decades of industry experience.