Why Food-Grade Facilities in Kansas City Need a Mechanical Partner Who Understands Sanitary Design

Running a food processing facility in Kansas City means more than just keeping the equipment running. It means meeting strict health and safety standards every single day. Your mechanical systems play a big part in that. If your contractor doesn’t understand sanitary design, you could be putting your product quality, inspection scores, and overall reputation at risk.

Sanitary design isn’t just about stainless steel and shiny surfaces. It’s about how systems are installed, how they’re maintained, and whether or not they support a clean and compliant production environment. At Anderson Mechanical, we’ve seen how the right mechanical setup can make all the difference in food-grade environments. And we’ve also seen how poor planning can lead to costly downtime, failed inspections, and safety concerns.

If you're operating a food or beverage facility in the Kansas City area, here's why choosing a mechanical contractor that understands sanitary design is essential.

Sanitary Design Starts with the Right Materials

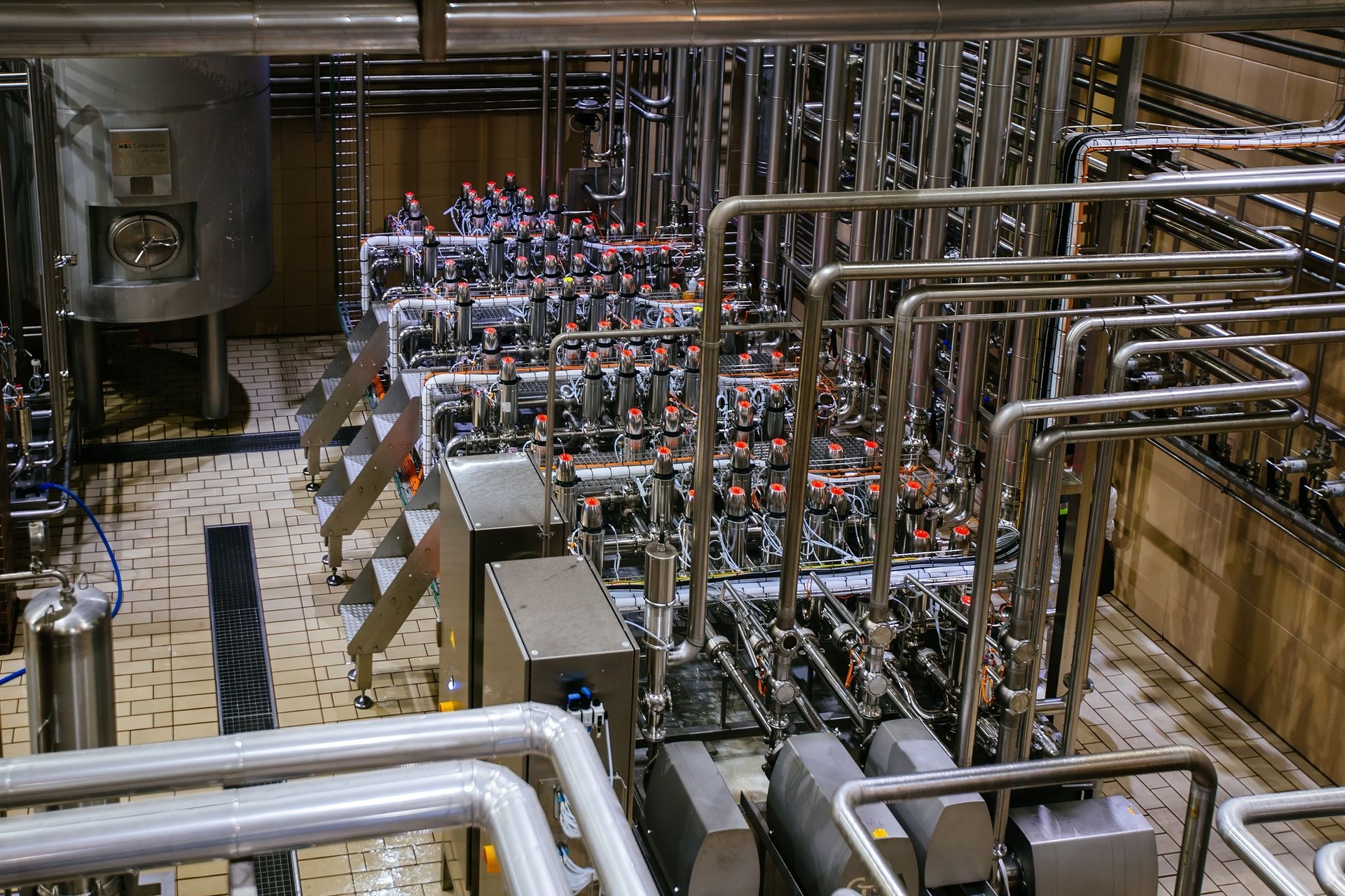

Let’s start with the basics. Materials matter in food-grade facilities. You need piping, valves, fittings, and support systems that are resistant to corrosion, easy to clean, and don’t trap contaminants. That typically means stainless steel, but even then, not all stainless steel is created equal.

Using the wrong grade of metal, or mixing metals that react poorly to each other, can create hidden problems. You can end up with pitting, cracking, or contamination. And once those issues start, they can be hard to spot until it’s too late.

A mechanical team that understands sanitary environments won’t just install the cheapest option. They’ll specify the right materials for the job and ensure compatibility across your entire system.

Layout Affects Cleanability

How your systems are laid out affects more than just efficiency. It also determines how easily your team can clean and inspect those systems. Dead legs in piping, sharp turns, or hard-to-reach valves are a recipe for trouble. These areas can collect residue or moisture that leads to bacteria growth or product contamination.

A clean layout means smooth piping runs, accessible connections, and thoughtful placement of components. It means designing the system not just to move product or air, but to keep that flow clean and consistent.

Anderson Mechanical works with plant managers and food safety teams to make sure the system layout supports your cleaning protocols and inspection requirements. We don’t just install what’s on paper. We build systems that make real-world operations smoother and safer.

Avoiding Cross-Contamination

In a facility where different products are processed in close quarters, cross-contamination is always a concern. Your mechanical systems need to be designed to minimize the risk of backflow, leaks, and mixing of incompatible materials.

That might mean including backflow prevention devices, installing dedicated lines for certain ingredients, or setting up pressure monitoring systems to alert you when something’s off. It also means keeping utilities like steam, water, and compressed air properly isolated from food contact surfaces.

An experienced mechanical partner understands these risks and builds systems that keep them in check.

Drainage and Moisture Control

Water is everywhere in a food plant. It’s used for cleaning, cooling, and sometimes directly in the product. But if it pools, drips, or collects in the wrong places, it becomes a hazard.

Your mechanical team needs to account for moisture during installation. That means sloped lines that drain fully. It means sealing penetrations in walls or floors. It means choosing components that don’t sweat or allow water to collect on surfaces.

In Kansas City’s variable climate, where humidity can spike in the summer and freeze in the winter, drainage and moisture management aren’t optional. They’re essential.

Air Handling Is Just as Important as Piping

It’s easy to focus on piping when talking about sanitary design. But air handling matters too.

In food-grade spaces, air needs to be clean, dry, and flowing in the right direction. HVAC systems should be designed to control humidity, temperature, and pressure. They should minimize dust, spores, or outside air intrusion. They should allow for easy filter changes and regular inspection.

And if your facility includes refrigeration or freezing systems, ventilation design becomes even more critical. You don’t want condensation or temperature swings introducing risk into the process.

Anderson Mechanical works with you to design air systems that support food safety from start to finish.

Proper Welds and Connections

When you’re dealing with food-grade piping, weld quality matters. Improper welds can leave behind crevices or rough surfaces where bacteria can hide. That’s why sanitary welds must be smooth, flush, and inspected for integrity.

You also need the right types of connections. In many cases, that means using clamp-style sanitary fittings instead of threaded connections. These allow for easier cleaning and reduce the risk of residue buildup.

Our team at Anderson Mechanical takes pride in precision welding and proper fit-up. We know that how something is joined is just as important as what it’s made of.

Maintenance Access Must Be Built In

No matter how well a system is installed, it needs to be maintained. That’s where many food-grade facilities run into trouble. If valves, filters, or sensors are buried behind walls or wrapped in hard-to-remove insulation, they’re less likely to get cleaned or checked.

A good mechanical layout makes maintenance easy. It allows your in-house team or service contractors to access what they need without disassembling half the system.

We build with service in mind. That includes planning for access panels, clean-out points, and clear labeling so your team knows exactly what they’re working with.

Compliance Isn’t a Guessing Game

Inspections from the USDA, FDA, or local authorities are no joke. When the inspector shows up, you want your mechanical systems to be the least of your concerns.

Having a partner who understands what inspectors look for is a huge advantage. We’ve worked in facilities that handle dairy, meat, produce, beverages, and baked goods, and we’ve helped our clients meet and exceed sanitary standards.

From material certifications to process documentation, we’re ready to support your compliance efforts from day one.

Kansas City Food Facilities Face Unique Challenges

In a city like Kansas City, where the weather changes fast and the demand for local food production is growing, your facility needs to stay flexible. You might be scaling up, adding a new product line, or retrofitting an older building. Each of those scenarios brings mechanical challenges that need a sanitary approach.

Our team understands how to work within your existing space and design systems that grow with you. Whether it’s a new piping run, an upgraded HVAC zone, or a full plant expansion, we approach every project with cleanliness and safety in mind.

Why Anderson Mechanical Is the Right Partner

You don’t want just any mechanical contractor working in your food-grade facility. You want a team that knows the difference between good enough and done right. You want a crew that shows up on time, respects your safety protocols, and gets the job done without cutting corners.

That’s what we do at Anderson Mechanical. We bring experience, attention to detail, and a real understanding of what food producers in Kansas City need from their mechanical systems.

From process piping to air handling, from installation to service, we’ve got the skills to keep your operation clean, efficient, and inspection-ready.

Final Thoughts

Sanitary design isn’t just a box to check. It’s a commitment to quality, safety, and long-term performance. When your mechanical systems are built with that in mind, everything else in your operation runs smoother.

If you're running a food-grade facility in Kansas City and need a mechanical partner who gets it, reach out to the team at Anderson Mechanical. We’ll take the time to understand your operation, walk your facility, and build a plan that supports your goals and your compliance standards. Let’s make sure your systems are as clean and reliable as your product.