The Essential Guide to Preventive Maintenance for Commercial HVAC and Mechanical Systems

The Essential Guide to Preventive Maintenance for Commercial HVAC and Mechanical Systems

Commercial and industrial facilities depend on reliable HVAC and mechanical systems to maintain daily operations. Whether your facility uses boilers, chillers, rooftop units, or VRF systems, maintaining peak equipment performance is critical for avoiding costly downtime and unexpected repair expenses. Preventive maintenance provides the proactive solution your business needs.

Preventive maintenance extends beyond routine inspections. It represents a strategic approach that maximizes equipment lifespan, optimizes energy efficiency, and ensures regulatory compliance while maintaining comfortable working conditions. Anderson Mechanical has served Kansas City commercial and industrial clients for over 20 years, witnessing how regular maintenance programs deliver measurable results.

Understanding Preventive Maintenance

Preventive maintenance involves scheduled inspections, cleaning, adjustments, and component replacements performed before equipment failure occurs. This proactive approach contrasts with reactive maintenance, which only addresses problems after breakdowns happen. The goal is identifying and resolving issues during their early stages.

HVAC System Preventive Maintenance Tasks

Commercial HVAC systems require comprehensive maintenance including:

- Air filter inspection and replacement

- Evaporator and condenser coil cleaning and inspection

- Blower motor testing and lubrication

- Thermostat and control system calibration

- Refrigerant level verification and pressure testing

- Ductwork inspection for air leaks and damage

- Electrical connection tightening and testing

Mechanical Equipment Maintenance Requirements

Boilers, chillers, and other mechanical systems need specialized attention:

- Combustion system and heat exchanger inspection

- Water level monitoring and flow rate verification

- Chemical balance testing and treatment

- Moving component lubrication

- Control system calibration and testing

- Safety system verification

Regular maintenance ensures optimal system performance and prevents premature equipment failure.

Key Benefits of Preventive Maintenance Programs

Extended Equipment Lifespan

Commercial mechanical systems represent significant capital investments. Properly maintained boilers, chillers, and rooftop units can operate efficiently for decades beyond their expected service life. Preventive maintenance reduces component wear and prevents minor issues from causing major system damage.

Following manufacturer-recommended maintenance schedules helps Kansas City facilities maximize their equipment investments while avoiding premature replacement costs.

Reduced Emergency Repair Expenses

Emergency repairs cost significantly more than scheduled maintenance. When critical equipment fails unexpectedly, businesses face repair costs, operational downtime, potential product loss, and premium emergency service fees.

Preventive maintenance identifies components approaching failure, allowing planned replacements during scheduled downtime rather than during emergency situations.

Improved Energy Efficiency

Dirty coils, incorrect refrigerant levels, worn belts, and malfunctioning sensors force HVAC systems to consume excessive energy. These inefficiencies directly impact utility costs and environmental performance.

Regular maintenance keeps equipment operating at peak efficiency. Kansas City businesses implementing comprehensive maintenance programs typically see substantial reductions in monthly energy expenses.

Enhanced Indoor Air Quality

Neglected HVAC systems circulate dust, allergens, and potentially harmful contaminants throughout facilities. Poor indoor air quality affects employee health, productivity, and comfort while creating potential liability issues.

Preventive maintenance includes thorough cleaning and inspection of air handling components, ensuring healthy indoor environments for all facility occupants.

Minimized System Failure Risk

Equipment failures during extreme weather conditions can be catastrophic. Rooftop unit failures during Kansas City summer heat waves or boiler problems during winter freezes create emergency situations affecting operations and occupant safety.

Routine inspections identify potential failure points such as worn motors, misaligned components, or corroded parts. Addressing these issues proactively prevents major system failures.

Regulatory Compliance and Safety

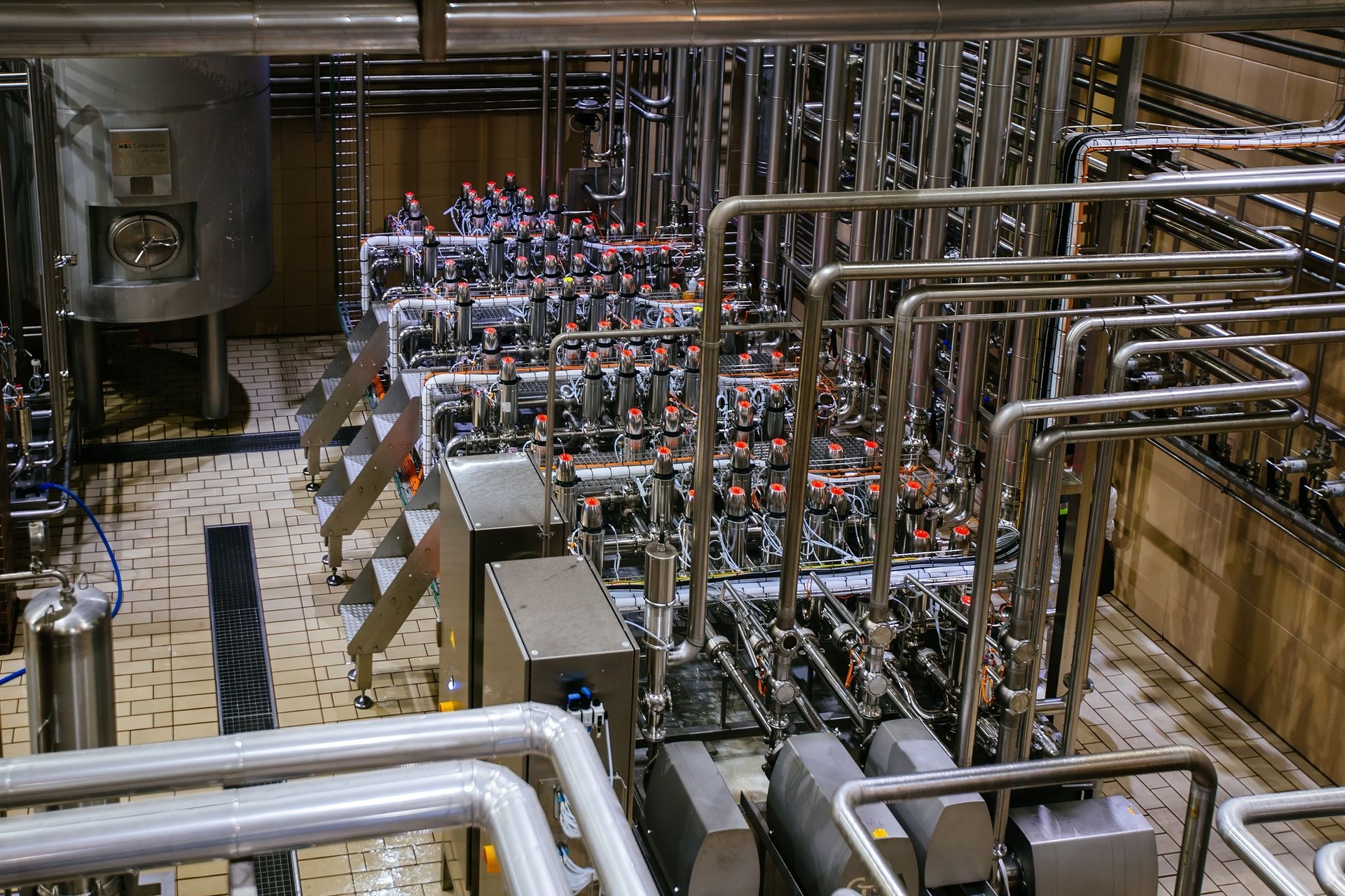

Industries with strict regulatory requirements, particularly food processing facilities, must maintain documented equipment inspection and maintenance records. Compliance failures can result in fines, operational shutdowns, and legal liability.

Anderson Mechanical specializes in sanitary food process piping systems and understands compliance requirements for regulated industries. Preventive maintenance programs help businesses maintain regulatory compliance while ensuring worker safety.

Typical Preventive Maintenance Procedures

HVAC System Maintenance

Comprehensive HVAC maintenance visits typically include:

- Complete system diagnostic testing

- Air filter replacement and airflow measurement

- Electrical connection inspection and tightening

- Refrigerant pressure and temperature verification

- Condensate drain cleaning and testing

- Moving component lubrication

- Control system calibration and programming verification

Chiller and Boiler Maintenance

Specialized mechanical equipment requires focused attention:

- Pressure relief valve inspection and testing

- Water treatment analysis and chemical adjustment

- Scale and corrosion assessment

- Burner and flame sensor cleaning and calibration

- Control system operation verification

- Safety interlock testing

Anderson Mechanical technicians follow equipment-specific checklists ensuring comprehensive maintenance without overlooking critical components.

Determining Maintenance Frequency

Optimal maintenance frequency depends on multiple factors:

- Equipment type, age, and manufacturer specifications

- Operating environment conditions including dust, humidity, and temperature extremes

- Daily operating hours and seasonal usage patterns

- Critical system applications and downtime sensitivity

Most commercial HVAC systems benefit from bi-annual servicing, with maintenance scheduled before peak cooling and heating seasons. Boilers and chillers may require quarterly inspections, especially in high-demand applications.

Anderson Mechanical develops custom maintenance schedules tailored to each facility's specific requirements, ensuring consistent service delivery without operational disruption.

Anderson Mechanical's Preventive Maintenance Solutions

Anderson Mechanical has provided reliable HVAC and mechanical system maintenance throughout Kansas City for over 20 years. Our experienced team maintains expertise in VRF systems, chillers, rooftop units, boilers, and specialized sanitary process piping systems.

Customized Maintenance Programs

Our preventive maintenance programs are designed around your specific equipment types, operating conditions, and business requirements. Whether managing small commercial facilities or large industrial operations, we develop maintenance plans that optimize system performance while fitting your operational schedule.

Certified Technician Expertise

Our technicians maintain certifications for major equipment brands including:

- Mitsubishi VRF systems

- Daikin VRF units

- LG VRF systems

- Various boiler and chiller manufacturers

This specialized training ensures proper maintenance procedures and warranty compliance for all equipment types.

Protecting Your Equipment Investment

Preventive maintenance investment goes beyond problem avoidance. It optimizes system performance, maximizes energy efficiency, and ensures long-term operational reliability. Facilities without recent HVAC or mechanical system inspections should prioritize establishing comprehensive maintenance programs.

Contact Anderson Mechanical to schedule equipment evaluations or discuss custom maintenance program development. Our team helps Kansas City businesses stay ahead of equipment problems while maintaining peak system performance.

Serving Kansas City, Lee Summit, Johnson County, and Jackson County with over two decades of mechanical contracting expertise, Anderson Mechanical delivers the preventive maintenance solutions your facility needs for continued operational success.