Strategic HVAC Retrofitting: Maximizing Performance and Cost Savings for Kansas City Commercial Facilities

Strategic HVAC Retrofitting: Maximizing Performance and Cost Savings for Kansas City Commercial Facilities

Commercial and industrial facilities in Kansas City depend on reliable HVAC systems for maintaining comfortable working environments, ensuring indoor air quality, and controlling operational costs. HVAC systems represent critical infrastructure investments that significantly impact energy expenses and occupant productivity. However, aging mechanical systems eventually require strategic decisions regarding repair, retrofit, or complete replacement.

HVAC retrofitting offers a cost-effective solution for improving system performance without the capital expense of full system replacement. Anderson Mechanical helps Kansas City businesses evaluate their equipment, analyze usage patterns, and develop long-term operational strategies. Understanding retrofit options enables informed decision-making that balances performance improvements with budget considerations.

Understanding HVAC Retrofitting

HVAC retrofitting involves upgrading or modifying existing system components to enhance performance, efficiency, or functionality without complete system removal. This strategic approach identifies underperforming or outdated components and replaces them with modern, efficient alternatives.

Common Retrofit Applications

Typical retrofitting projects include:

- Variable speed drive installation on motors and fans

- Smart thermostat and programmable control system upgrades

- Economizer and energy recovery ventilator additions

- High-efficiency chiller and boiler replacements

- Ductwork improvements and air sealing modifications

Retrofitting suits facilities with aging HVAC infrastructure that require performance improvements without full system replacement investments.

Identifying Retrofit Requirements

Several indicators suggest HVAC systems would benefit from strategic retrofitting:

Escalating Energy Costs

Steadily increasing utility expenses without corresponding usage increases often indicate declining system efficiency. HVAC systems working beyond optimal parameters consume excessive energy, creating opportunities for retrofit-based cost reductions.

Frequent Maintenance Requirements

Aging systems typically experience increased breakdown frequency and maintenance demands. Constant service calls, temperature inconsistencies, and equipment reliability issues suggest strategic component upgrades could improve overall system performance.

Obsolete Control Systems

Legacy systems often rely on basic thermostats or manual controls lacking modern automation capabilities. Control system retrofits provide enhanced oversight, automated operation, and improved energy management functionality.

Indoor Environment Quality Issues

Occupant complaints regarding air quality, humidity levels, or temperature fluctuations indicate system performance deficiencies. Retrofitting can address airflow and ventilation problems without requiring complete system replacement.

Regulatory Compliance Requirements

Businesses may need to meet updated building codes, energy efficiency standards, or internal sustainability targets. Retrofitting helps achieve compliance objectives without major capital expenditures.

Benefits of Strategic HVAC Retrofitting

Enhanced Energy Efficiency

Replacing inefficient components, upgrading motors, or installing energy recovery systems substantially reduces energy consumption. Long-term savings often offset initial retrofit investments through reduced utility costs.

Improved System Performance

Modern controls, enhanced airflow management, and reliable components create more responsive HVAC systems. Improved responsiveness delivers consistent comfort levels and reduces operational disruptions.

Extended Equipment Lifespan

Strategic retrofitting extends useful equipment life rather than requiring complete system replacement. This approach maximizes existing infrastructure investments while improving performance.

Reduced Environmental Impact

Energy consumption reductions lower facility carbon footprints, supporting sustainability initiatives and preparing for future environmental regulations.

Proven Retrofit Solutions

Variable Speed Drive Technology

Variable speed drives enable motors and fans to operate at variable speeds based on actual demand rather than constant full-power operation. This technology significantly reduces energy consumption and component wear.

Building Automation Systems

Modern control platforms enable programmed scheduling, zone-based temperature management, and remote monitoring capabilities. These systems provide energy savings and operational data for informed decision-making.

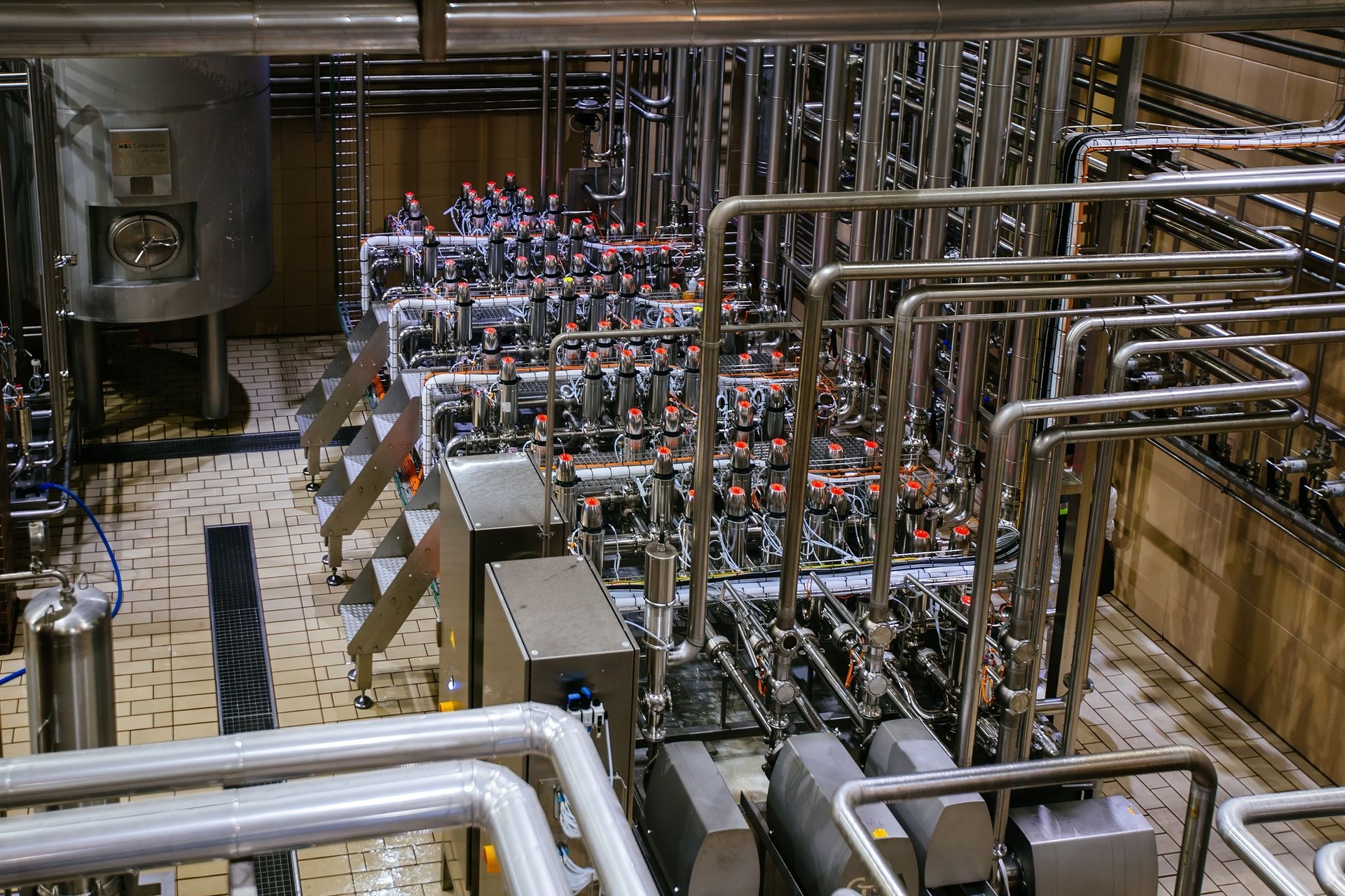

High-Efficiency Equipment Replacement

Replacing outdated boilers or chillers with modern, high-efficiency units improves reliability while reducing energy consumption. Anderson Mechanical services both air-cooled and water-cooled chiller systems, helping select optimal solutions for specific building requirements.

Energy Recovery Technologies

Economizers enable HVAC systems to utilize cool outdoor air for cooling rather than relying solely on mechanical refrigeration. Energy Recovery Ventilators reclaim energy from exhaust air to condition incoming fresh air, improving efficiency in high-ventilation applications.

Anderson Mechanical's Retrofit Process

Comprehensive System Evaluation

Our technicians conduct thorough on-site inspections of existing HVAC infrastructure, review performance history, and analyze utility data. This evaluation identifies current performance levels, problem areas, and improvement opportunities.

Customized Recommendation Development

We develop tailored retrofitting options based on specific system requirements, facility characteristics, and operational objectives. Recommendations include cost estimates, implementation timelines, and projected energy savings calculations.

Professional Installation Services

Our certified technicians complete retrofit installations with minimal operational disruption. We coordinate work schedules around business operations and critical facility requirements.

Performance Verification Testing

Following retrofit completion, we conduct comprehensive system testing to verify performance improvements, efficiency gains, and reliability enhancements meet project expectations.

Anderson Mechanical's Retrofit Expertise

Anderson Mechanical has provided HVAC services throughout Kansas City for over 20 years. Our team maintains expertise with commercial chillers, boilers, rooftop units, VRF systems, and comprehensive mechanical equipment. We develop customized solutions based on each building's specific requirements and usage patterns.

Our retrofit recommendations consider cost reduction objectives, reliability improvements, and future operational growth requirements. This comprehensive approach ensures HVAC investments deliver long-term value and operational benefits.

Evaluating Retrofit Opportunities

Facilities with aging but functional HVAC systems often benefit most from strategic retrofitting approaches. Professional evaluation helps determine optimal upgrade strategies that balance performance improvements with investment requirements.

Contact Anderson Mechanical to schedule retrofit consultations for your Kansas City facility. Our team will evaluate your property, assess current equipment performance, and develop retrofitting strategies aligned with your operational objectives and budget parameters.

Serving Kansas City, Lee Summit, Johnson County, and Jackson County with over two decades of commercial HVAC expertise, Anderson Mechanical delivers retrofit solutions that maximize system performance while controlling costs.